Virtual Power Plants: Taming Disruptive DER (Part 1 of 2)

Posted on May 3rd, 2019Navigant Research recently wrote, “The proliferation of distributed energy resources (DER) will be among the most disruptive trends to the traditional energy industry over the next decade.” The unpredictable and uncontrollable nature of millions of Distributed Energy Resources (DER) and microgrids is among the challenges facing energy companies, electric utilities and the grid operators. A concept called a “virtual power plant” or VPP may help bring more order to the grid and the electric industry. This two-part article will examine why DER is considered “disruptive” and how VPP might help address those challenges.

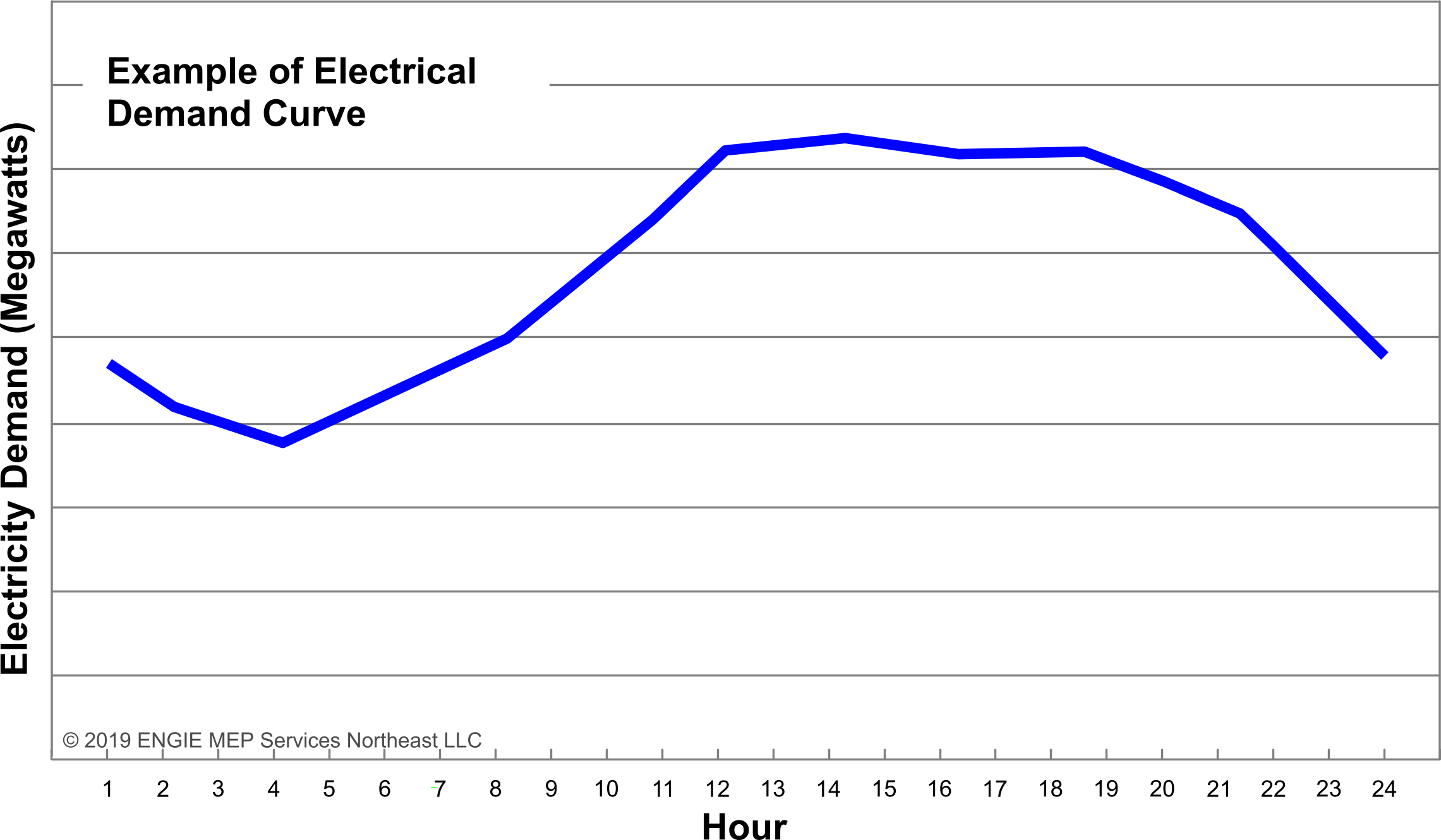

Figure 1

The Way It Was

A little more than a decade ago, supplying electricity to meet the demand was predictable. The daily demand for electricity (Figure 1) would begin to increase in the early morning as businesses started up and would peak in mid-afternoon often driven by the need for air conditioning. After the midday peak, demand would fall throughout the night reaching its lowest point around 3 AM to 4 AM after which the cycle would begin anew.

To respond to the daily electrical demand cycle, grid operators could look at the weather forecast, the day of the week and a few other details and know with a high degree of certainty how they would “dispatch” generating plants (e.g. start/stop or increase/decrease output) under their control. The operators would start using plants with the lowest generating cost and would dispatch increasingly more costly plants as needed to meet the peak demand. Today, the widespread use of DER has introduced a large degree of uncertainty into this formerly predictable process.

Duck Curves – Quack! Quack!

Distributed Energy Resources and microgrids utilize a variety electrical sources including fuel cells, microturbines, internal combustion engines, battery storage systems, solar photovoltaic panels and wind turbines. And, while the vast majority of these generating sources are very small compared to a 700 MW baseload power plant, there are literally millions of these small sources feeding electricity into the grid across the country. In the parts of the country with the largest concentration of DER, especially wind and solar, the daily electrical demand curves have significantly changed in recent years.

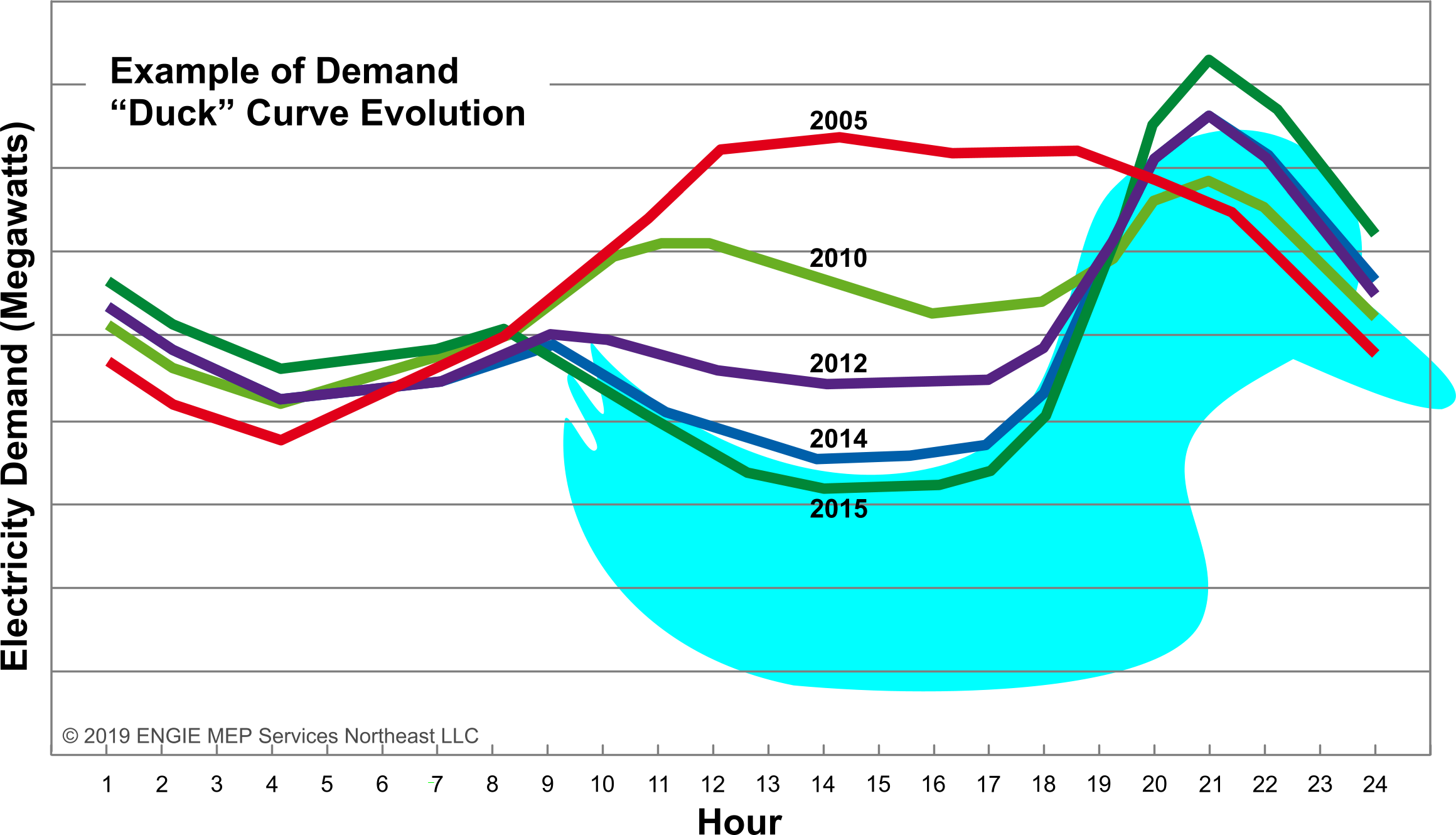

Figure 2

Figure 2 shows the evolution of what are called “Duck Curves” for obvious reasons. As DER installations rapidly multiplied, the peak of demand curves became depressed to such an extent that the midday peak turned into an evening peak. However, when the sun doesn’t shine or the wind doesn’t blow, the daily demand has to be met by conventional power plants. Nonetheless, Duck Curves represent both good news and bad news.

The good news is that efforts to increase the use of renewable energy sources and cleaner and more energy efficient DER have been and continue to be successful. For example, the amount of electricity generated by renewable sources in the U.S. doubled between 2008 and 2018 and represent nearly 18% of the total generation in the U.S. today. Furthermore, nearly 90% of this increase is attributable to wind and solar additions. More good news is that DER are lessening the load on transmission & distribution systems as well as reducing the need to build new large power plants.

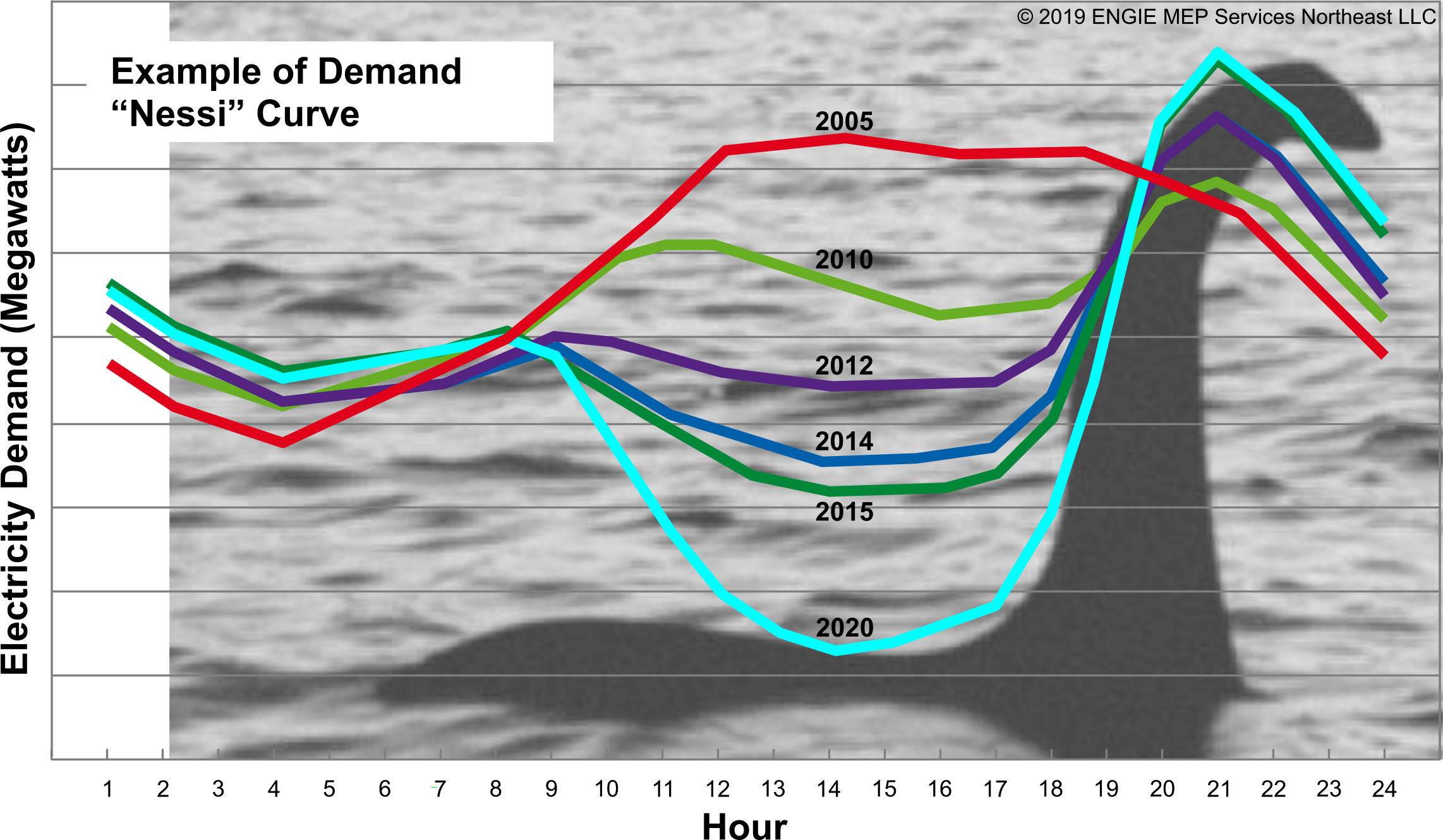

The bad news is that increasing the amount of DER is moving Duck Curves to “Nessi Curves” (Figure 3). The increasing verticality of the curve in the “neck” means that electrical demand rockets upwards from the daily low to the daily peak demand. This greatly reduces the time and generating options grid operators have to respond to the peak demand. Generating resources capable of such daily rapid starts and stops to meet the short-term demand increases tend to be more expensive to operate than conventional baseload plants.

Figure 3

More Bad News

Another piece of bad news is that most DER are so small and connected to the grid in such a way that their operation isn’t “visible” to grid operators. Unlike utility power plants which grid operators can dispatch and constantly monitor, no such control or monitoring is available for the majority of DER and microgrid installations. Grid operators don’t know whether a DER installation can supply electricity to the grid and, if so, when, how much or for how long. This puts grid operators in a situation analogous to driving a car in which some unseen force pushes on the accelerator at random times.

DER also create another problem for many energy companies and electric utilities: declining revenue due to a reduction in electricity sales. The continuing growth of DER installations will only further exacerbate the revenue decline and make investment decisions more challenging.

Eliminating Uncertainty

In the second part of this article, we’ll examine the Virtual Power Plant (VPP) and how it works to resolve the complications posed by DER. Even before a local VPP is available, however, facility owners and managers should clearly understand one critical point:

“The risks are increasing for facilities purchasing electricity, but

the risks decrease for facilities with Distributed Energy Resources”.

The disruptive trend of DER on energy companies and utilities will continue no matter what facility owners do. Owners should focus on protecting their own facilities from an uncertain future of power quality problems, interruptions and increases in electricity prices.

Trystate takes a holistic approach to facility energy usage and risks. Before sizing and designing a DER system, a facility should be operating at optimum efficiency to avoid oversizing. That’s why in addition to providing Distributed Energy Solutions, Trystate also offers a full range of facility energy-related services, including:

- ASHRAE energy audits (I, II & III)

- Certified TABB and NEBB services

- New and existing building commissioning – BCxA

- LEED AP and CEM services.

Trystate Mechanical Inc. is a proud member of the Equans MEP Services family of companies and leader of Combined Heat & Power (CHP) projects for the company throughout the U.S.

EQUANS MEP Services designs, builds and maintains a complete range of mechanical, digital and energy systems to increase the comfort, efficiency, reliability and value for owners and representatives of facilities all types. The combination of more than 700 professionals, extensive in-house technical, fabrication and project capabilities plus the resources of the worldwide EQUANS Group enables us to provide innovative financing, energy, power, project and related solutions of unequaled breadth and value.